What Exactly Is an API Plant?

An API plant is a manufacturing facility where these active ingredients are produced at industrial scale. These plants can range from relatively small, specialized labs to large, complex factories covering chemical synthesis, fermentation, purification, and drying operations. API plants are designed to handle sensitive and often hazardous substances under strict environmental, safety, and quality controls. Their role is critical: without API plants, pharmaceutical companies wouldn’t be able to formulate finished drugs. These facilities ensure that every batch of API meets the required standards for purity, potency, and consistency key attributes for patient safety.

How Are APIs Manufactured in These Plants?

API manufacturing is a multi-step process that depends on the nature of the compound being produced. For small-molecule chemical synthesis is commonly used, involving several reaction and purification steps. For biologics or biosimilars, the API may be produced using living cells through biotechnology processes like fermentation or cell culture. Once the API is synthesized or harvested, it undergoes purification (such as crystallization or chromatography), drying, and milling before it’s packaged for use in drug formulation. Throughout each step, strict Good Manufacturing Practices (GMP) are followed to ensure the safety, stability, and reproducibility of the final product.

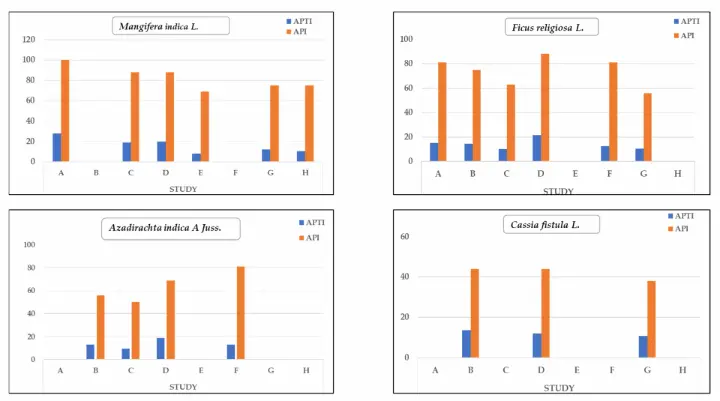

Variations of APTI and API in the four different plants from eight different studies.

Why API Plants Are Vital to the Pharma Supply Chain

API plants form the backbone of the pharmaceutical manufacturing process. Their ability to produce high-quality, affordable active ingredients directly impacts drug availability, pricing, and public health outcomes. In recent years, the world has seen how disruptions in API productionwhether due to pandemics, trade issues, or regulatory challenges can severely affect the global drug supply. Many countries depend heavily on a few regions (notably India and China) for APIs, creating concerns about supply chain resilience. As a result, there is increasing global interest in building more localized and diversified API production capabilities to safeguard medicine accessibility and independence.

The Future of API Plants: Innovation and Sustainability

The future of API manufacturing is being shaped by innovation, automation, and sustainability. Technologies like continuous manufacturing, AI-driven process monitoring, and synthetic biology are helping API plants become more efficient, safer, and environmentally responsible. At the same time, regulators and governments are encouraging pharmaceutical companies to bring production closer to home to reduce dependency on global supply chains. The growing demand for personalized medicine and complex biologics also means API plants must be more agile and adaptive than ever. As the pharma industry evolves, API plants will remain critical ensuring that essential medicines are always within reach for patients around the world.